Positive Displacement Pump

Piston, Plunger or Diaphragm pumps

Transmission Chain Centre is one of the Leaders in Manufacturing and Dealer of Positive Displacement Pump

Transmission Chain centre one of the foremost dealer of Positive Displacement Pump in India. This pump is primarly used for High Viscos liquids and semi Solids such as Resins, Paints, pastes or Bitumen. The pump works on the concept of pushing by first isolating a certain fixed volume of material and then forcing it out in a particular direction.

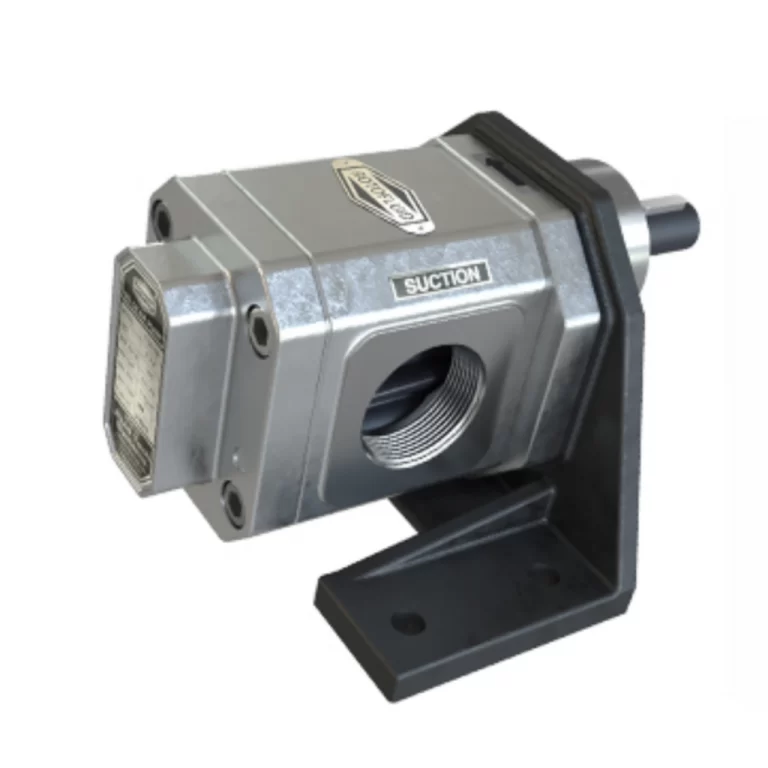

We at Transmission Chain Centre offer the “ROTOFLUID” brand Piston or Plunger pump Models “FTRN, FTRB, FTRX” Also know as Positive Displacement Pump, External Gear Pump, Molasses Gear Pump or Rotary Twin Gear Pump. This type Plunger pump has a heavy duty foot mounting, It has a positive displacement rotary twin gear pump which works with the help of a diaphragm. Model “FTRN/FTRB/FTRX” having three piece construction it can be easily cleanable and maintainable. These pumps having a double helical refined gear and hardened grind finished shaft, double helical gear help to prevent axial load & side thrust which greatly increase the pumps life and its performance.

These pumps are having flange at the end of suction and delivery which are available in 1/2″ to 6″ size. These pumps can be operated up to pressure of 10 kg/cm² with 8.30 LPM to 2083.00 LPM flow capacity. These pumps are suitable for liquid up to viscosity of 1, 00,000 SSU and maximum temperature up to 200ºc.

Positive displacement pump Selection for Models FTRN/FTRB : The self lubricated needle roller bearing type Model FTRN used for clean viscous liquid having sufficient lubricating property such as clean lube oil, Gear oil, Animal oil, Fish oil, Hydraulic oil, Honey, Vegetable oil, SAE lubricating oil for continues duty, However for Intermittent duty Bush Bearing type pump Model FTRB used.

For Model FTRX : This Model independent lubricated needle roller bearing type pump is suitable for handling of Crude oil, Dirty lube oil, HSD, Kerosene, LDO, Paints, Varnish, Wood Pulp, Liquid which have poor lubricant value.

For Model FTRBJ : This Model should be selected for liquid which tends to solidify at room temperature such as Bitumen, Furnace oil, Asphalt, Tar, Starch, Molasses, Naphtha, RFO, Silicate, Wax, Soap solution. Because This model have jacketing construction facilitate the heating the pump by steam or thermic fluid.

Download documents .elementor-column.elementor-col-50.elementor-inner-column.elementor-element.elementor-element-016aa99 { background: linear-gradient(135deg,#003861 0,#009ee0 100%); margin-right: 2px; } .elementor-column.elementor-col-50.elementor-inner-column.elementor-element.elementor-element-4c3bebb { background: linear-gradient(135deg,#003861 0,#009ee0 100%); margin-right: 2px; } .elementor-element.elementor-element-11658d8.elementor-widget.elementor-widget-image { width: 50px; height: 50px; margin-left: auto; margin-right: auto; } .elementor-element.elementor-element-f886268.elementor-widget.elementor-widget-image { width: 50px; height: 50px; margin-left: auto; margin-right: auto; } .elementor-element.elementor-element-fc1229c.elementor-widget.elementor-widget-image { width: 50px; height: 50px; margin-left: auto; margin-right: auto; } video.elementor-video { width: 100%; height: 380px; } div#vid { margin-top: 90px; }

Contact Us .disable_link{text-decoration:none!important;text-align: center;color:white}

Positive displacement pump Technical Specification

section.elementor-section.elementor-top-section.elementor-element.elementor-element-1700d10.elementor-section-boxed.elementor-section-height-default.elementor-section-height-default {

padding-top: 15px;

padding-bottom: 15px;

background-color:#F5F5F5;

}

.elementor-column.elementor-col-100.elementor-top-column.elementor-element.elementor-element-d111a42{

width: 1170px;

margin-left: auto;

margin-right: auto;

}

section.elementor-section.elementor-top-section.elementor-element.elementor-element-1700d10.elementor-section-boxed.elementor-section-height-default.elementor-section-height-default {

padding-left: 70px;

padding-right: 40px;

}

Model FTRN/FTRB/FTRX

Suction & Delivery Size

Capacity at 1440 RPM

LPM

US GPM

M³/hr

050-S

1/2" x 1/2"

10.00

2.64

0.60

050-M

1/2" x 1/2"

15.00

3.96

0.9

050-L

1/2" x 1/2"

25.00

6.60

1.50

100-S

1" x 1"

30.00

7.92

1.80

100-M

1" x 1"

50.00

13.20

3.60

100-L

1" x 1"

60.00

15.85

3.60

150-S

1½" x 1½"

80.00

21.13

4.80

150-M

1½" x 1½"

100.00

26.41

6.00

150-L

1½" x 1½"

125.00

33.02

7.50

200-S

2" x 2"

150.00

39.62

9.00

200-M

2" x 2"

165.00

43.58

9.90

200-L

2" x 2"

200.00

52.83

12.00

250-S

2 ½" x 2 ½"

250.00

66.04

15.00

250-M

2 ½" x 2 ½"

300.00

79.25

18.00

250-L

2 ½" x 2 ½"

330.00

87.17

19.80

300-S

3" x 3"

415.00

109.63

24.90

300-M

3" x 3"

450.00

118.87

27.00

300-L

3" x 3"

500.00

132.08

30.00

400-S

4" x 4"

600.00

158.50

36.00

400-M

4" x 4"

665.00

175.67

39.90

400-L

4" x 4"

830.00

219.26

49.8

500-S

5" x 5"

1000.00

264.17

60.00

500-M

5" x 5"

1250.00

330.21

75.00

500-L

5" x 5"

1500.00

396.25

90.00

600-S

6" x 6"

1650.00

435.88

99.00

600-M

6" x 6"

1825.00

482.11

132.00

600-L

6" x 6"

2083.00

549.47

124.80

.center {

margin-left: auto;

margin-right: auto;

}

.tabletitle {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

background-color: #08488b;

font-size: 18px;

font-weight: 700;

color: white;

text-decoration: none;

}

.tablerow {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 18px;

color: #333;

text-decoration: none;

background-color: #ffff;

}

.tablerow1 {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 18px;

color: #333;

text-decoration: none;

background-color: #efefef;

}

| Model FTRN/FTRB/FTRX | Suction & Delivery Size | Capacity at 1440 RPM | ||

| LPM | US GPM | M³/hr | ||

| 050-S | 1/2" x 1/2" | 10.00 | 2.64 | 0.60 |

| 050-M | 1/2" x 1/2" | 15.00 | 3.96 | 0.9 |

| 050-L | 1/2" x 1/2" | 25.00 | 6.60 | 1.50 |

| 100-S | 1" x 1" | 30.00 | 7.92 | 1.80 |

| 100-M | 1" x 1" | 50.00 | 13.20 | 3.60 |

| 100-L | 1" x 1" | 60.00 | 15.85 | 3.60 |

| 150-S | 1½" x 1½" | 80.00 | 21.13 | 4.80 |

| 150-M | 1½" x 1½" | 100.00 | 26.41 | 6.00 |

| 150-L | 1½" x 1½" | 125.00 | 33.02 | 7.50 |

| 200-S | 2" x 2" | 150.00 | 39.62 | 9.00 |

| 200-M | 2" x 2" | 165.00 | 43.58 | 9.90 |

| 200-L | 2" x 2" | 200.00 | 52.83 | 12.00 |

| 250-S | 2 ½" x 2 ½" | 250.00 | 66.04 | 15.00 |

| 250-M | 2 ½" x 2 ½" | 300.00 | 79.25 | 18.00 |

| 250-L | 2 ½" x 2 ½" | 330.00 | 87.17 | 19.80 |

| 300-S | 3" x 3" | 415.00 | 109.63 | 24.90 |

| 300-M | 3" x 3" | 450.00 |

118.87 | 27.00 |

| 300-L | 3" x 3" | 500.00 | 132.08 | 30.00 |

| 400-S | 4" x 4" | 600.00 | 158.50 | 36.00 |

| 400-M | 4" x 4" | 665.00 | 175.67 | 39.90 |

| 400-L | 4" x 4" | 830.00 | 219.26 | 49.8 |

| 500-S | 5" x 5" | 1000.00 | 264.17 | 60.00 |

| 500-M | 5" x 5" | 1250.00 | 330.21 | 75.00 |

| 500-L | 5" x 5" | 1500.00 | 396.25 | 90.00 |

| 600-S | 6" x 6" | 1650.00 | 435.88 | 99.00 |

| 600-M | 6" x 6" | 1825.00 | 482.11 | 132.00 |

| 600-L | 6" x 6" | 2083.00 | 549.47 | 124.80 |

Additional Information

section.elementor-section.elementor-top-section.elementor-element.elementor-element-3666099.elementor-section-boxed.elementor-section-height-default.elementor-section-height-default {

padding-top: 15px;

padding-bottom: 15px;

}.elementor-column.elementor-col-100.elementor-top-column.elementor-element.elementor-element-1a33f23 {

width: 1170px;

margin-left: auto;

margin-right: auto;

}

section.elementor-section.elementor-top-section.elementor-element.elementor-element-2f2a84d.elementor-section-boxed.elementor-section-height-default.elementor-section-height-default {

padding-left: 70px;

padding-right: 40px;

}

.elementor-column.elementor-col-50.elementor-top-column.elementor-element.elementor-element-e32af18 {

padding-top: 40px;

width: 45%;

}

.elementor-column.elementor-col-50.elementor-top-column.elementor-element.elementor-element-f9f8646 {

width: 55%;

}

.elementor-601 .elementor-element.elementor-element-f9f8646:not(.elementor-motion-effects-element-type-background) > .elementor-widget-wrap, .elementor-601 .elementor-element.elementor-element-f9f8646 > .elementor-widget-wrap > .elementor-motion-effects-container > .elementor-motion-effects-layer {

background-color: #FFFFFF;

padding-top: 40px;

padding-left: 40px;

padding-right: 40px;

}

ul {

margin-left: 20px;

}

h2.specific_head {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 36px;

color: #1f1f1f!important;

font-weight: 500;

margin-bottom: 0px;

}

Features

h3.power_head {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif!important;

font-size: 34px;

color: #fff;

line-height: 1.4em!important;

font-weight: 500;

margin-bottom: 0px;

}

h3.key_head {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif!important;

font-size: 34px;

color: #000;

line-height: 1.4em!important;

font-weight: 500;

margin-bottom: 0px;

}

h3.item-title {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 24px;

color: #1f1f1f!important;

line-height: 2em;

font-weight: 500;

}

h5.subheadings {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 18px;

color: #1f1f1f!important;

line-height: 2em;

font-weight: 500;

margin-top: 15px;

margin-bottom: 15px;

}

h3.degree_head {

font-family: 'Montserrat',Helvetica,Arial,Lucida,sans-serif;

font-size: 24px;

color: #1f1f1f!important;

line-height: 2em;

font-weight: 500;

}

- Heavy duty gear pump design for continuous application.

- Herringbone rotor design eliminate side thrust.

- Modified tooth profile enhance tooth life.

- Floating gear design ensures uniform load distribution.

- Optionally steam jacket available.

- Double helical gear design prevent axial load.

- Low leakage path by design improve volumetric efficiency.

- Shorter bearing span reduces bending effect.

Application

- Petroleum industries.

- Bitumen plant.

- Power plant.

- Steel plant.

- Cement plant.

- Refineries.

- Pumping station.

- All kind of liquid loading and unloading.